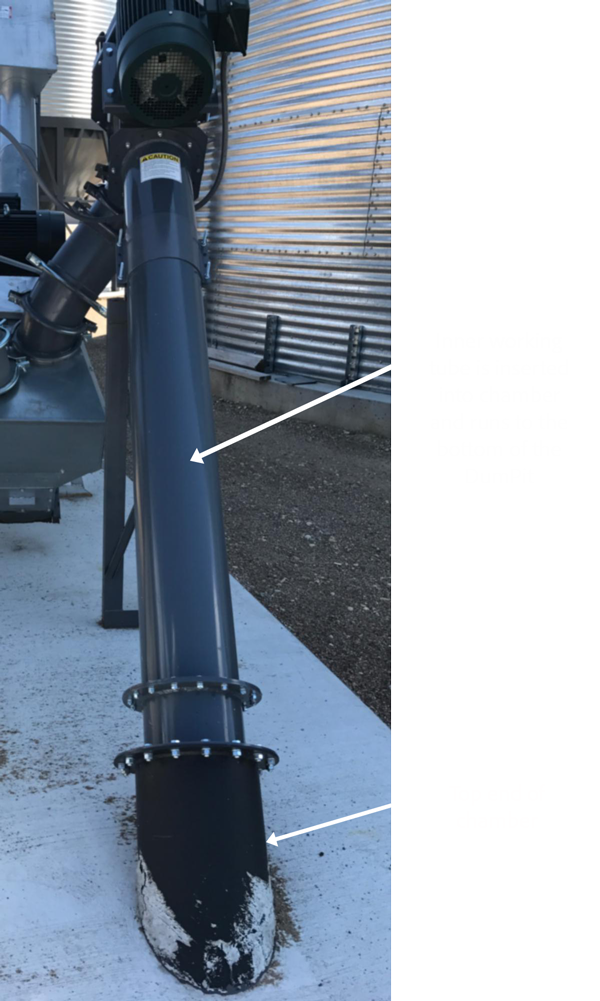

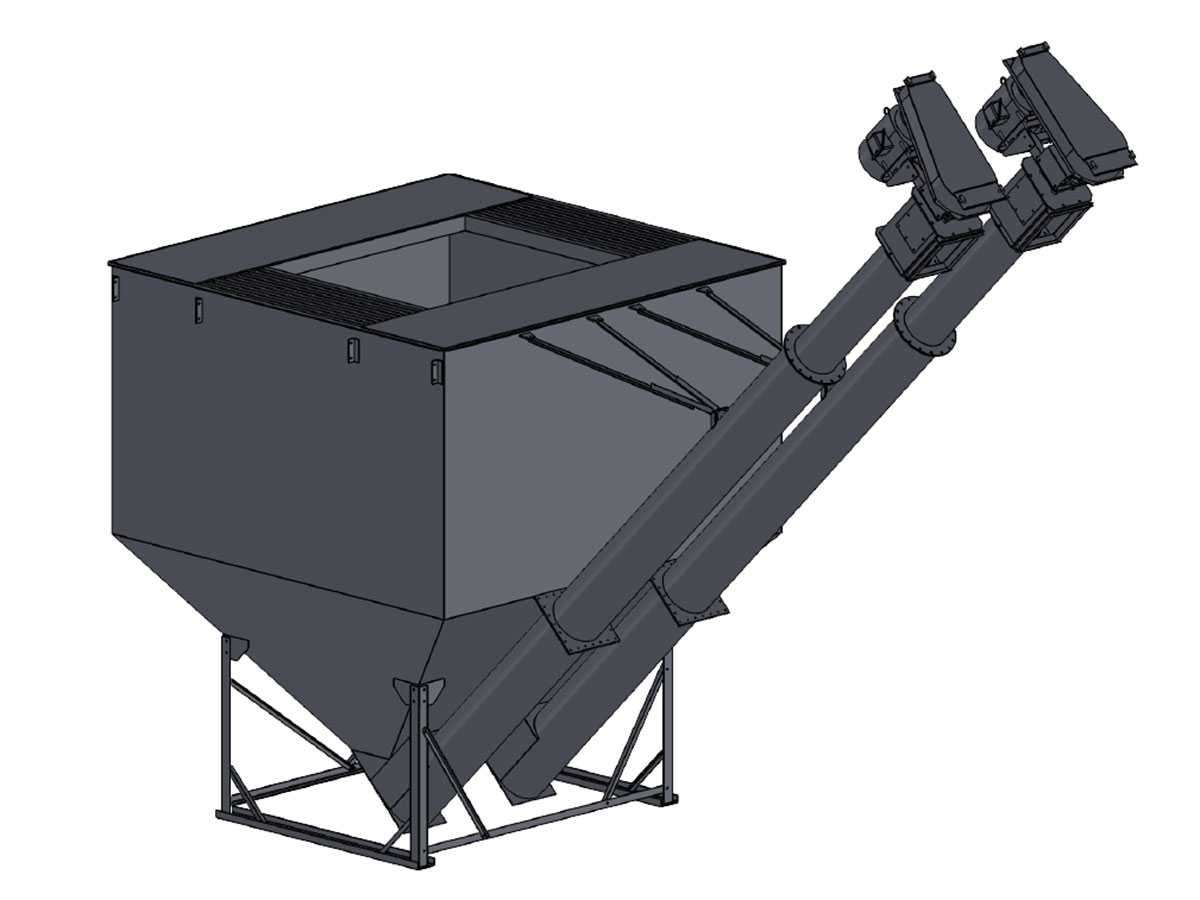

The DumPit inner working tube is inserted through the chamber down into the boot at the bottom of the DumPit. The chamber is mostly buried in the ground with the top flange just above ground level.

Lowry Augers - Standard

DumPit boot welded to the bottom of a DumPit

DumPit 3/8" flighting

Abrasion Resistant (AR) flighting for auger intake

Lowry augers are heavy-duty, built with 3/8" flighting and 3/16" tube. Abrasion-resistant (AR) flighting is used at the intake to increase the longevity of the auger. To protect your DumPit, a boot and chamber tube are welded to the bottom of the pit to house the inner working tube.

Auger parts, except the chamber, are designed to be serviceable. This is to increase the life of your DumPit, ensuring that all moving and wearable parts are replaceable.

A nylatron foot bearing is located at the bottom of the auger and may be replaced from inside the DumPit. It is recommended to check your foot bearing to ensure its integrity before the start of each harvest season.

Lowry Augers - Spliced Flights

Some auger flights are spliced due to:

the overall length (for shipping purposes), or

it needs to be in two pieces because of obstructions at the site during installation.

Lowry has developed two servicing options for installing, inspecting and replacing spliced flights. The tube service panel and tube service port allow for the spliced connection to be easily accessed. Either option can be used and is a matter of preference. For safety reasons, these panels should never be removed while the DumPit is in operation.

IMPORTANT STEP! WELD HELICOIL TOGETHER: Spliced flights should be spun together, making sure the bottom helicoil overlaps the top helicoil. The connection should be squeezed together and welded on both sides. This is sometimes overlooked, causing a flight to be noisy or fail prematurely.

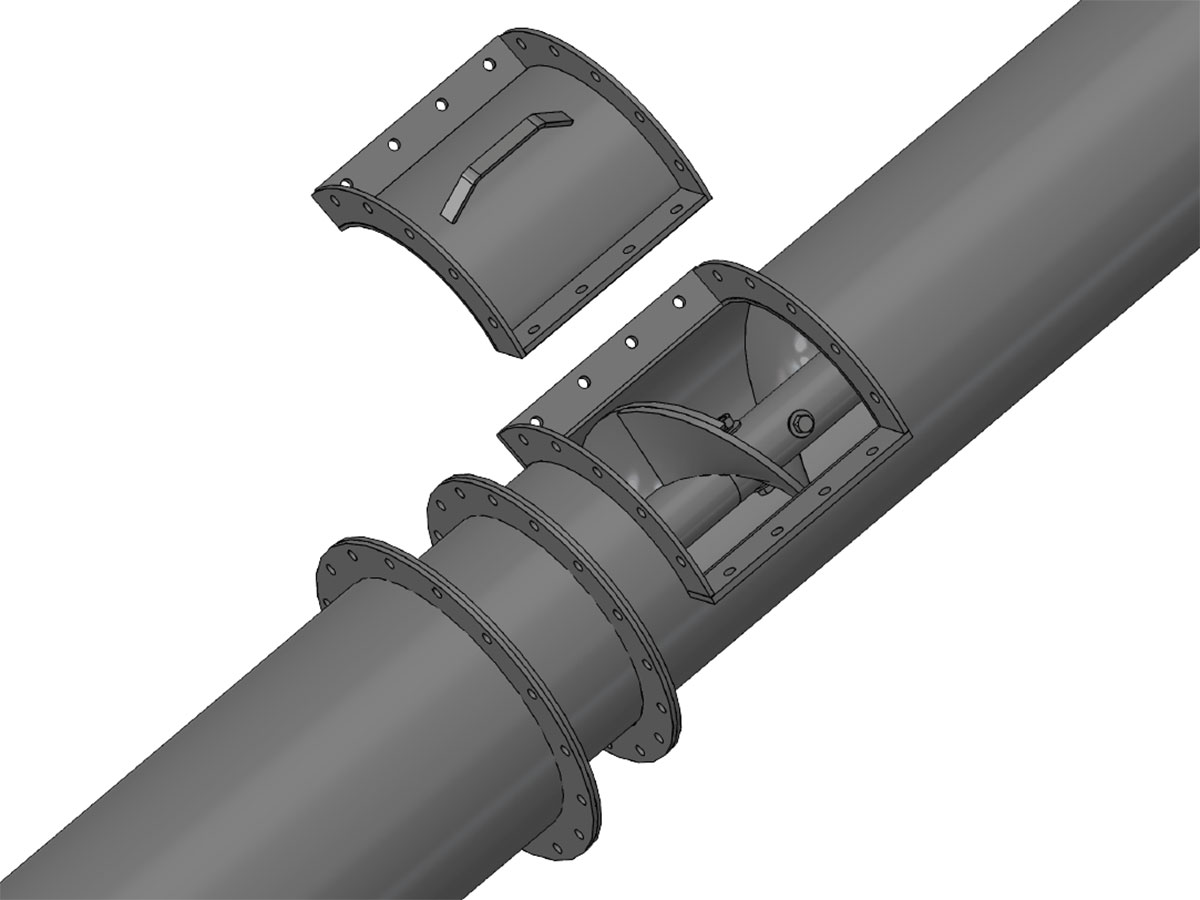

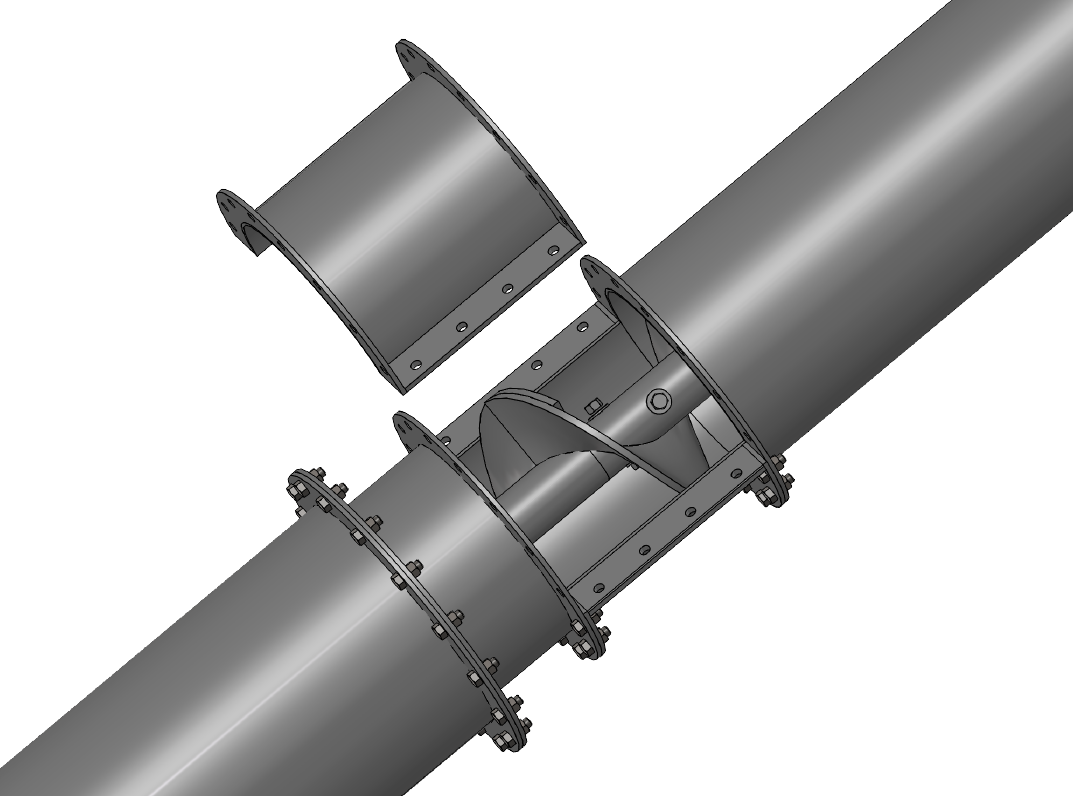

Tube Service Port

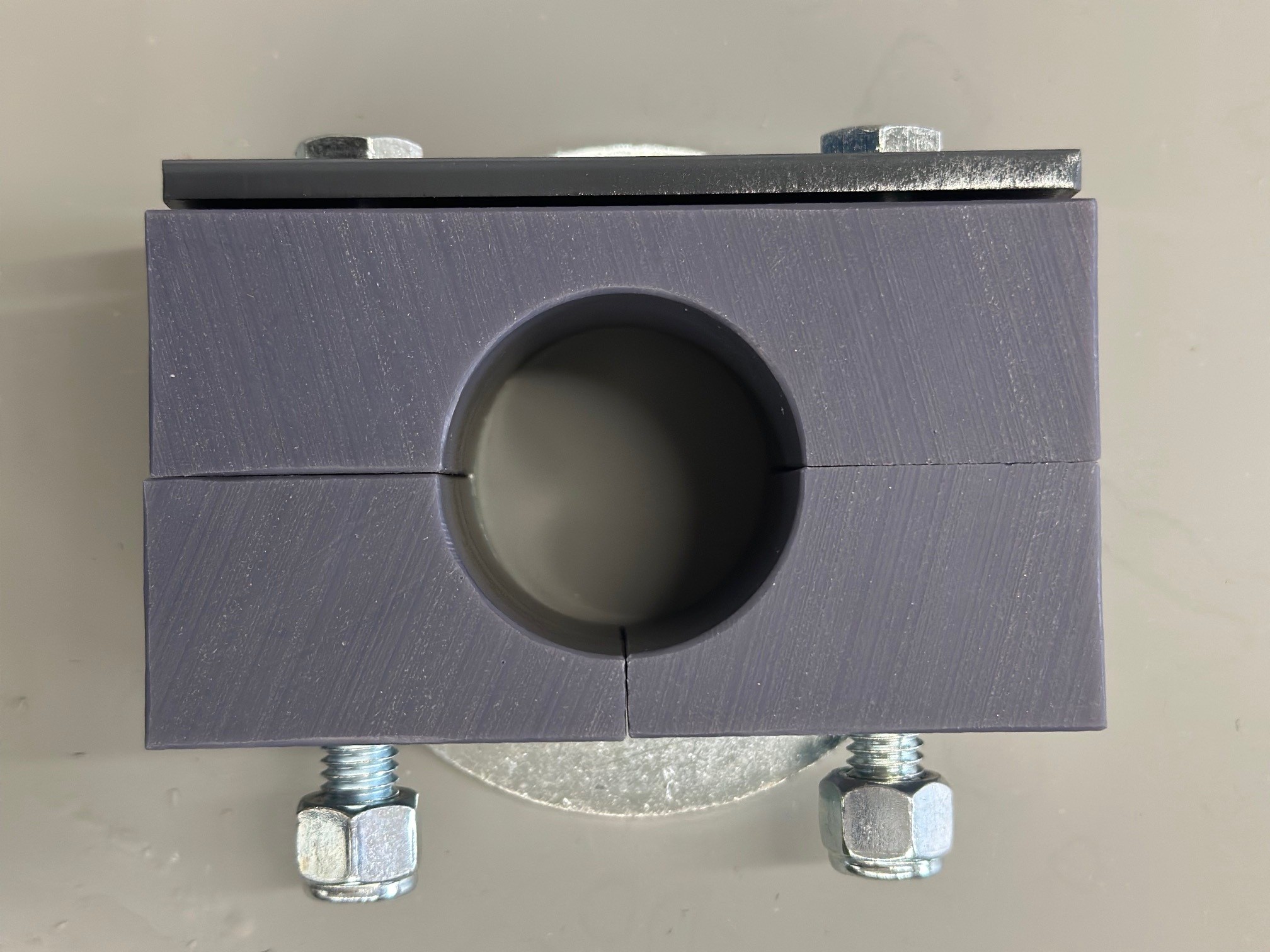

DP Tube Service Port

Tube Service Port:

A service port is a standalone part with a removable section where the splice in the flighting is located. The top of the service port may be unbolted and removed to expose about half of the inside. The service port has flanges on the edges that are bolted to flanges on the connecting tubes and the other half of the service port.

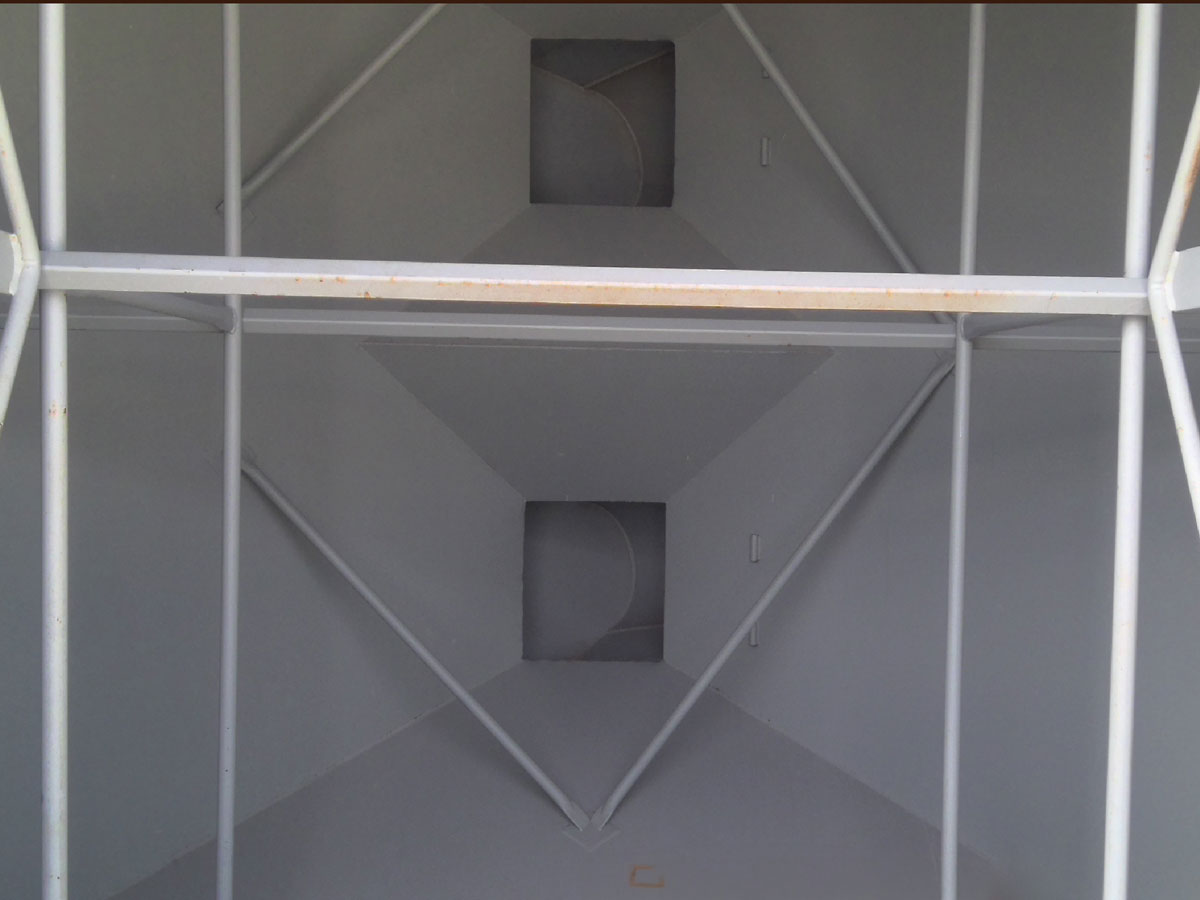

Lowry Augers - Twin Augers

DumPit with twin augers (laying on its side).

DumPit with twin augers – inside of pit

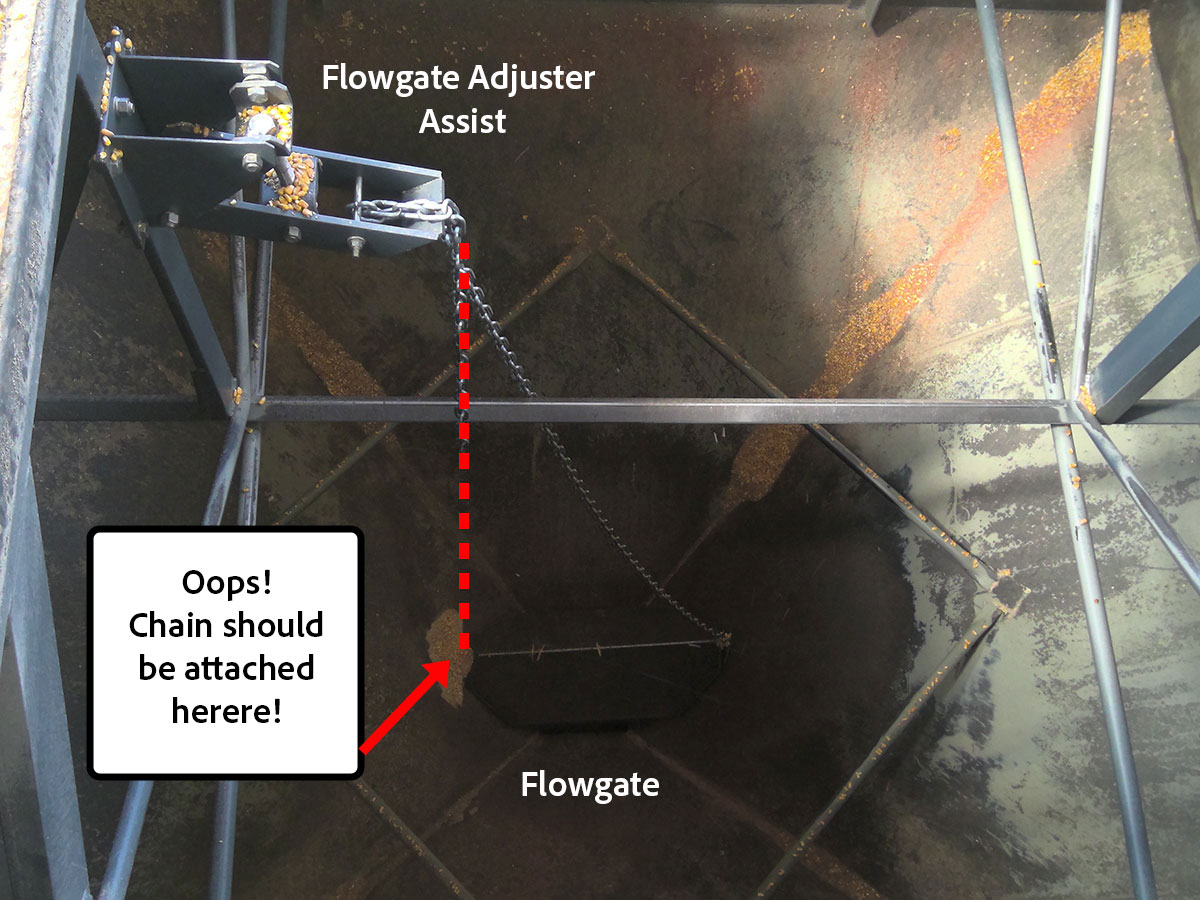

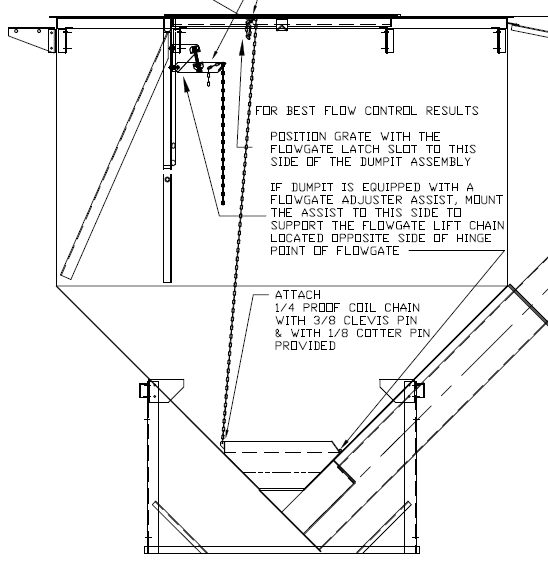

An important installation tip is to make sure the chain is almost straight up and down from the flowgate (at the bottom) to the latch on the removable grate or the flowgate adjuster assist (at the top).

Do not run the chain diagonally from the flowgate to the grate (as shown in the image), it won’t work as effectively when grain falls across the chain.