Safety Features - Dust Management at the Grain Receiving Station

The Problem:

The Solution:

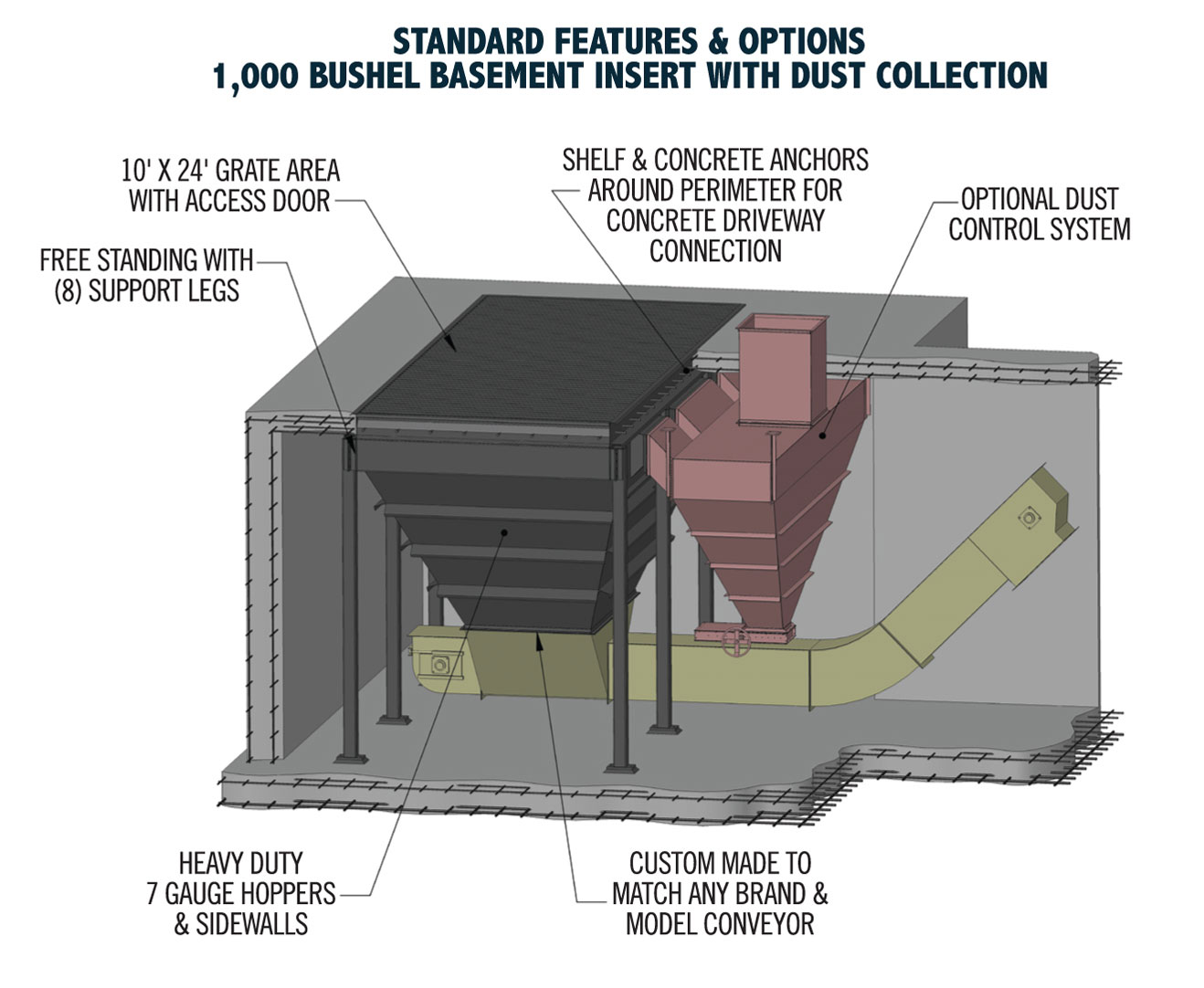

The Lowry Manufacturing Co. design team developed a dust-collection system that can be built into a basement insert to remove particulate-filled air. The system has undergone extensive engineering to ensure that the proper volume of air is pulled from the basement insert-resulting not only in a cleaner, but a much safer environment. The design also allows for the reintroduction of captured particles back into the grain stream. Dust control is a big concern for grain operations because regulations may mandate that the area in and around a grain-handling facility must maintain acceptable air-quality standards. Systems designed by Lowry Manufacturing that are already in operation have been thoroughly tested and have proven to resolve those issues.

Basement Insert - High Capacity Receiving Pit - With Dust Control Option

The Lowry Basement Insert is a good solution for high-volume or commercial operations. When used in conjunction with a conveyor system, a 1,000-bushel or larger pit can be unloaded considerably faster than a conventional pit, and with less potential damage to grain (an important factor when working with seed-quality grains). The open basement setup allows for easy access to the conveyor for maintenance.